Rotator strona główna

-

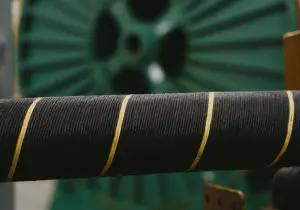

Hartlepool Power Cable Load Out

Our team at JDR Hartlepool recently achieved a significant milestone with the successful and safe carousel load out of the Export and Inter Array Cables for LES EOLIENNES FLOTTANTES DU GOLFE DU LION, the pilot Floating Offshore Wind Farm project.

-

New Blyth Facility progress

JDR Cable Systems (JDR), the global subsea cable and umbilical supplier and servicer, part of the TFK Group, has announced its plans to open a new state-of-the-art subsea cable manufacturing facility in Cambois, near Blyth, Northumberland.

-

TFKable Group

TFKable is a global leader in the production of high and extra-high voltage cables, specializing in the energy sector, with a proven track record of deliveries for power grid operators and positive results from production process audits conducted by renowned certification bodies.

About JDR

EolMed floating wind

JDR has secured a contract to supply, test, and terminate 66kV dynamic inter-array cables (IAC) for Qair’s Eolmed 30MW floating offshore wind project near Gruissan, France. The project will connect to the French grid, supplying power to 50,000 residents. JDR will design and manufacture the cables, with core production at TFK's Bydgoszcz plant in Poland and final assembly at JDR’s Hartlepool facility, the UK. Installation is planned for late 2024, supporting France’s target of 40GW offshore wind capacity by 2050.

Hail and Ghasha

The world’s first net-zero gas project will capture 1.5 million tonnes of CO₂ annually, storing it underground while using low-carbon hydrogen and clean power from nuclear and renewables. Supporting the UAE’s gas self-sufficiency goal, JDR will design and manufacture four subsea umbilicals (7-48 km), one of the largest projects in the region, integrating steel tubes, power cores, and fiber optics for essential power and communication.

132kV Subsea Cable Qualification for Offshore Energy

JDR has qualified its new 132kV static array cable for next-gen offshore wind turbines, enabling high-voltage, UK-manufactured cables that support larger turbines and greater distances. Supported by the Offshore Wind Growth Partnership and tested at ORE Catapult, the cable will be produced at JDR’s Hartlepool and new Cambois sites.

State-of-the-art subsea cable manufacturing facility in Cambois

In September 2021, JDR Cable Systems, part of TFK Group, announced a £130 million investment in a subsea cable manufacturing facility in Cambois, Northumberland. Spanning 69,000 sqm, this cutting-edge site will create 171 local jobs, and produce high-voltage subsea cables, positioning JDR at the forefront of the offshore wind market.

TFKable Group

TFKable and JDR Cable Systems, both leading manufacturers in the cable industry, proudly operate under the TFKable Group. As a unified entity, they combine their expertise to deliver high-quality subsea and land cable solutions for the renewable energy sector. With a shared history of innovation and successful projects, their collaboration strengthens the supply chain and drives advancements in high and extra-high voltage cable systems. Their partnership reflects their commitment to excellence, providing comprehensive insights into their capabilities, projects, and future developments.

Strona Główna - Baner

Houston Service Center

Assembly, integration and testing of umbilicals, reelers and associated packages. Houston-based project management and engineering support is available for projects in the Gulf of Mexico, as well as offshore commissioning, testing and repair work.

Environmental

JDR promotes sustainability through initiatives including the Science Based Targets Initiative (SBTi), UN Global Compact, and the Copper Mark assurance framework with TFKable

Health and Safety

JDR has placed a strong focus on mental health awareness, aligning with national initiatives to enhance workplace support

STEM

For over 13 years, JDR Cables has supported communities through charitable and STEM initiatives

Corporate Social Responsibility

At JDR and as part of the TFK.Group, we continue to promote and adopt the publication of an annual Sustainability Report as a means of consolidated disclosure of our non-financial information, with specific reference to environmental, social and staff-related issues, respect for human rights and the fight against bribery and corruption. The document is prepared in accordance with GRI Sustainability Reporting Standards.

JDR are committed to protecting human rights and oppose all forms of human trafficking and forced labour in our supply chains.

-

27th August 2025

27th August 2025JDR to electrify Eni’s Liverpool Bay Transportation and Storage project with power cable supply, helping deliver HyNet North West

-

8th July 2025

8th July 2025JDR to support offshore umbilical testing in the Middle East under L&T contract

-

12th June 2025

12th June 2025JDR Cable Systems completes type test qualification of next generation 132kV subsea cables for offshore energy applications

-

14th January 2025

14th January 2025JDR supports cutting-edge IceCube neutrino research in Antarctica’s extremes